Animal product analogues have been around for a while.

Alternative Dairy products, extracted from vegetables include soy, oat and almond milks.

Similarly meat analogues have been made using vegetable proteins including gluten and soy, in combination with other ingredients to provide tastes, textures and visuals that are often designed to mimic those of meat products including bacon, sausages, meat patties etc.

Most of these products were intended to either provide vegan / vegetarian “alternatives”, and for some to avoid dairy allergen or lactose intolerance.

Increasingly environmental sustainability has become a driver for moving away from products derived from intensive livestock farming to production of synthetic ingredients and food: dairy proteins, cultured meat and novel cellular proteins for example.

Farming of cattle, sheep, pigs and poultry results in high emissions of greenhouse gasses directly from the animals as well as from the husbandry practices (fuel for farming and transport and feed production). Emissions of nitrogen into soils and waterways is also a feature of pastoral agriculture. For many the desire for synthetic food products also includes elimination of animal welfare concerns associated with traditional farming and harvesting practices.

Many synthetic foods will require raw material inputs from agriculture with the associated environmental costs of inputs but with the anticipated benefits of:

Better conversion rate of feeds to product outputs (only the edible part is produced – no organs, bones, fur, feathers or scales)

Significantly reduced water use

Limited discharges of nitrogen to soils and waterways

Significantly lower overall requirement for agricultural land reducing the need for ongoing destruction of natural ecosystems, and allowing land to be returned to nature

Today, the direct dollar costs of producing many synthetic foods is generally orders of magnitude higher than that of traditional agriculture. However, as these new technologies mature, costs will come down.

The ultimate in minimising environmental impact is represented by systems that utilise minimal inputs – Gases from the air (such as nitrogen, carbon dioxide and oxygen), water and a small amount of nutrients, driven using renewable electricity. However many will still require huge investment and traditional agriculture (typically plant based) to produce inputs (sugars, amino acids and lipids) for the growth media in sufficient purity and quantity.

A range of different synthetic food production technologies are discussed below.

Cell Culture:

Growing foods in bioreactors or fermentation vessels provides the opportunity to greatly reduce the physical space required for food production, whilst simultaneously moving to a more sustainable future.

There are two key areas currently being explored intensively with the target of reducing humanities reliance upon traditional agriculture. It may be considered that cell culture is at the heart of these technologies.

The first is to grow animal cells to replicate the flesh of farm animals, fish and poultry: cultivated meat.

The second is to utilise fermentation: either directly as foodstuffs (Biomass Fermentation), or to produce specific compounds to be used as functional ingredients in foods (Precision Fermentation).

There are challenges to commercialising synthetic foods, though there are numerous governments, research facilities, and companies working in this space. Requirements for commercial success of such products include having:

the technical capability to produce the foods economically

sufficient customers willing to purchase and consume the food

legislation allowing these novel foods to be traded

Cell-cultured meat:

From the first synthetic meat made in 2013 in a Dutch laboratory, to commercial sale of synthetic chicken in Singapore in 2021, the scale and diversity of cultured meat continues to expand. However it remains a drop in the proverbial ocean of global meat consumption.

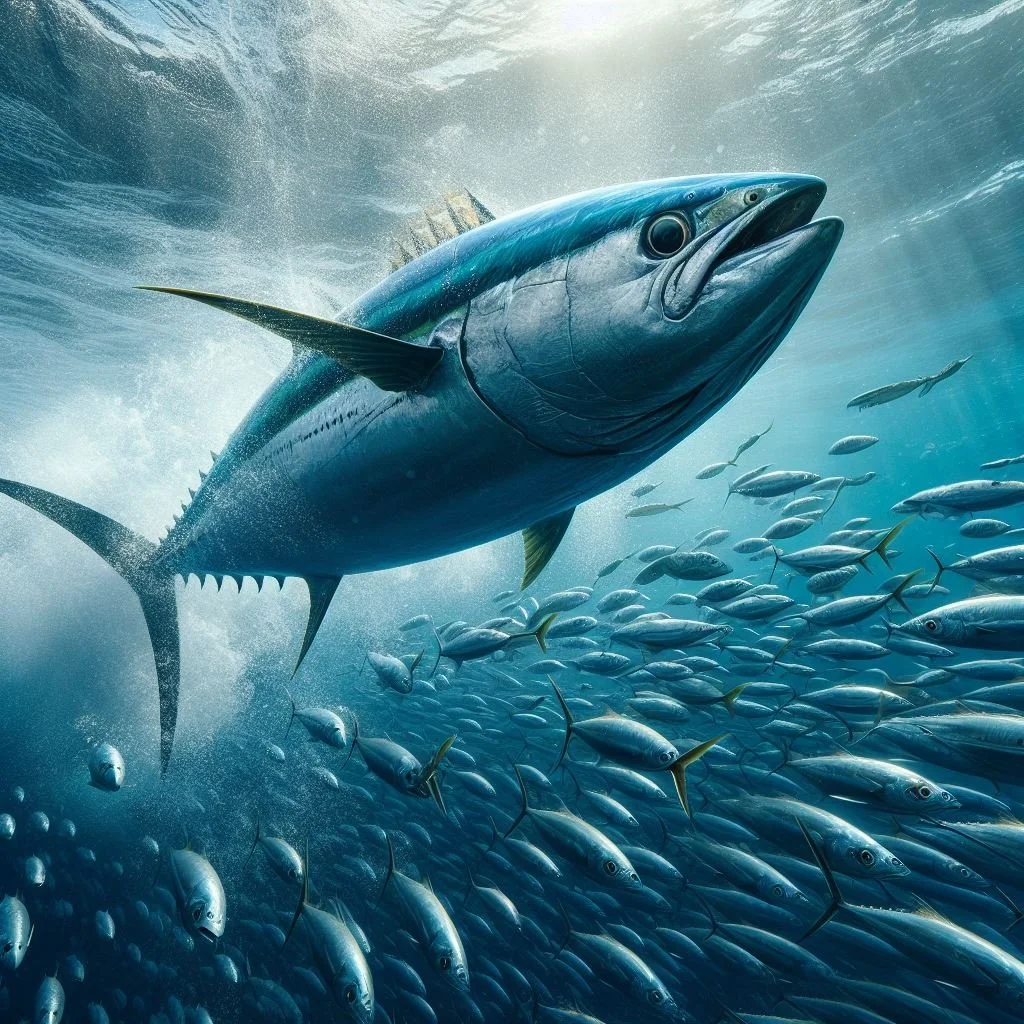

Work is being done creating meat from a range of farm animals (beef, pork & chicken) and fish species (including eel, bluefin tuna and carp). Other companies are working on providing meat from “exotic” species: products people wouldn’t ordinarily consume, but the novelty factor adding “value”.

The starting point for this process is typically stem cells that are extracted from live animals. The stem cells, in an appropriate environment, will multiply and differentiate into muscle cells, collagen and fatty tissue, producing structures very similar to skeletal muscles from farmed animals. The Nutritional characteristics are equivalent to those of the parent animal.

Many companies are operating in this space, though few are producing products for commercial sale.

Singapore is seeking to reduce its reliance on imported foods and their Government has legislated accordingly. Singapore became the first country in which cultured meat was permitted to be sold to consumers – in the form of cultured chicken nuggets briefly in 2021, and currently cultured chicken via a Butchery & Bistro. Only very limited quantities of cell cultured chicken are available.

The US approved 2 companies for sale of cell cultured meat in mid 2023 – to be sold as “cell-cultivated chicken”. Very small quantities are available to the public via restaurants the businesses have partnered with.

Although widely anticipated to have a significantly lower environmental impact than traditional farming, different studies have produced vastly different outcomes in terms of environmental impacts. Only as the cultivated meat industry scales up will compelling data become available.

In order for cell cultured meat to scale to a level that has a meaningful impact on global food supply, the following developments are required:

Growth Media: This is essentially the equivalent of blood plasma – providing the environment for cellular growth. Traditionally Foetal Bovine Serum has been used at key stages culture, but this is both extremely expensive, and requires beef processing at scale to produce it. Developing an animal free culture medium is high on the priority list for most organisations involved. However the components must be of very high quality and purity to avoid contamination (microbiological & chemical). Preparing the perfect balance of sugars, amino acids lipids and growth factors requires a whole suite of inputs and manufacturing processes. It’s unlikely these materials will be easy to produce at scale, or cheap to ramp up.

Meat Structure: For many potential consumers, having products that replicate the products they are used to is critical. Fermenters can produce tissue cells – akin to sausage meat in structure once separated from the culture media. A range of technologies are being developed to provide either bio-scaffolding or other means to encourage growth in natural meat like portions containing muscle, collagen, and fat tissues in appropriate proportion and structure.

Scaling up: To displace an appreciable volume of meat sourced currently from agricultural practices, huge volumes of meat will need to be cultivated. Currently the bioreactors are relatively small and conducted in conditions suitable for pharmaceutical grade products. The cells being cultured have no immune system, so rely upon the culture environment and all inputs being free of microbes – viruses, bacteria, yeast. All phases of cell culture will need to remain free from biological contamination throughout the process. So not only will the scale need to become vast to bring down costs, but to maintain the required hygiene the infrastructure and inputs will need to be “sterile”.

Regulatory Considerations: Only two countries have regulatory environments that permit the sale of cultured meat – Singapore and the US. Issues that currently arise in many jurisdictions include the use of hormone growth promoters which is banned in the EU and many other areas. The definition of these products needs to be settled in most countries, and this includes the naming – is it actually meat or muscle. How the food safety Hazards are addressed also needs to be determined be each country. Finally several countries have banned cell cultured meat!

Fermentation:

Bacteria, algae and fungi have been used for millennia to produce foods and beverages. However in relation to synthetic foods most applications would produce novel products.

Biomass Fermentation: utilises the whole organism, typically protein rich, as the foodstuff. Species are selected based on the characteristics desired. Some sources in addition to providing excellent amino acid profile, also offer modest amounts “healthy” lipids, fibre and nutrients such as vitamins and minerals. Genetic modification may be used to enhance the nutritional profile of the organism, or the substrates from which it is cultured. Biomass fermentation probably offers the most significant opportunity for the reduction of resources used to create synthetic foods in comparison to traditional farming. Many companies are currently using fermented biomass to produce “meat-like” analogues and provide viable alternatives to animal based agricultural products.

Precision Fermentation: Utilises microorganisms to produce functional products – typically proteins (including enzymes), but possibly also lipids and vitamins. This technique has been used for decades to produce Insulin for diabetics, and rennet for cheese making – pharmaceuticals and high value food components. Most applications rely upon gene manipulation (Genetic Engineering) to produce the intended product efficiently. The target genetic material is inserted into a host organism which operates as a “cellular factory” churning out the target material in large quantity very efficiently. Current food focussed developments include:

milk proteins (casein, lactoferrin)

meat proteins (myoglobin, collagen)

egg proteins

Lipids

These technologies may allow the transition from dairy cow based human infant nutrition to utilisation of human identical milk components.

Precision fermentation products are likely to contribute to improving the nutritional profile, taste & texture of non-animal foods to provide more “authentic” meat analogues. This may also play a significant role in providing components for the growth media for cell-cultured meat.

One significant issue associated with precision fermentation is the “unnaturalness” of such materials. GMO foods are currently highly controlled in many countries and avoided by many consumers.

Outlook:

Biomass fermentation is in widespread use in the production of food alternatives to traditional animal farming and will continue to increase its market share as new technological developments are made.

Similarly Precision fermentation has been used for decades to produce high value proteins, enzymes, vitamins and food colours. Advancements in gene manipulation technologies has opened the door to wide ranging advancements in this field. These will be cheaper to produce and utilise significantly fewer resources than those from traditional sources. New products will increasingly be available improving nutritional values.

The most challenging technology to commercialise in a meaningful way will be cell-cultured meat. Costs have reduced by several orders of magnitude from the initial successes a decade ago. However, significant developments are required to allow cost parity with traditional agriculture. Hurdles that need to be overcome include sourcing culture media that is not from animal source and scaling up to very high volume production.

The synthetic food sector is moving at pace and one of the greatest limitations is the regulatory environment which typically does not keep pace with science and technology.